close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

AEC500C

coso

Product Description

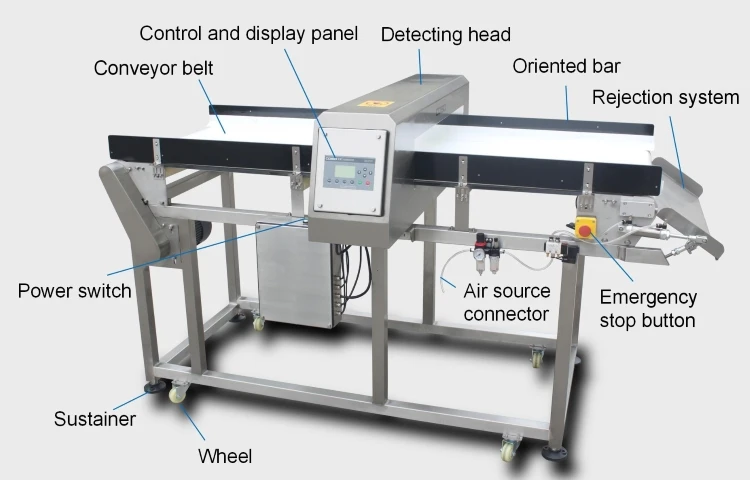

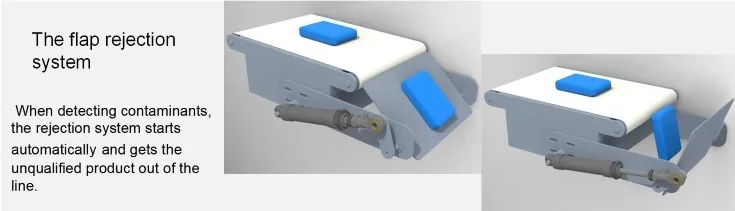

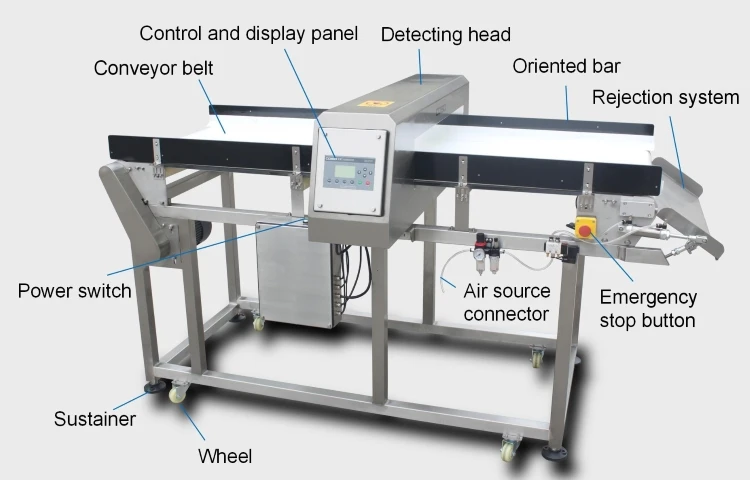

The COSO Metal Detector with Flap Rejection is designed for high-precision detection of metal contaminants in food, pharmaceutical, and packaging industries. Featuring a high-sensitivity detection system, this metal detector efficiently identifies and removes ferrous, non-ferrous, and stainless steel contaminants to ensure product quality. With its automatic flap rejection system, contaminants are immediately ejected from the production line, reducing the risk of contamination and ensuring smooth, uninterrupted operations. The detector is fully customizable with options for waterproof, dust-proof, and explosion-proof designs to meet the specific needs of your production environment.

Application

Product Details

Key Features

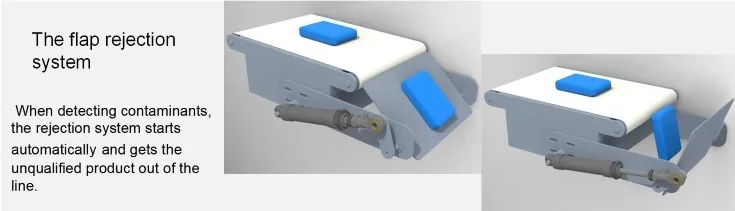

Flap Rejection System for automatic contaminant removal

High-Sensitivity Detection for accurate impurity identification

Customizable Design for specific industry needs

Ideal for food, pharma, and packaging industries

Produc Parameter

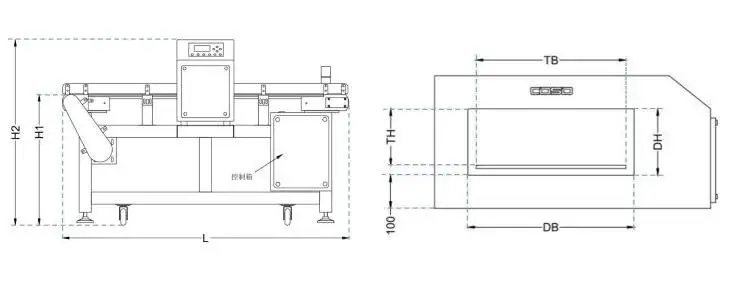

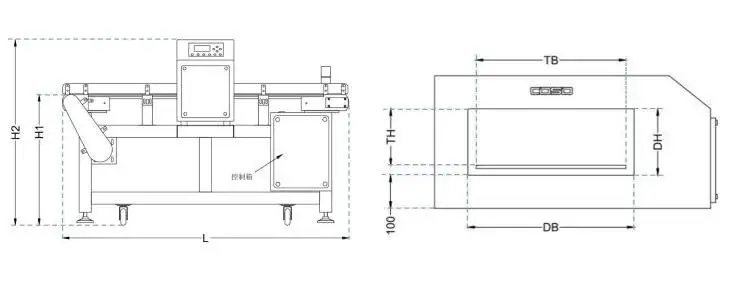

H1: Height from conveyor belt to the ground DB: Width of tunnel

H2: Height of whole machine TB: Passing width

L: Length of conveyor belt DH: Height of tunnel

W: Width of whole machine TH: Passing height

| Model | Size of whole machine(mm) | Size of detecting head(mm) | Best sensitivity(mm) | ||||||||

| H1 | H2 | L | W | DB | TB | DH | TH | Fe | Non-Fe | SUS | |

| 3008 | 700 | 850 | 1200 | 650 | 300 | 250 | 80 | 50 | 0.8 | 1.0 | 1.5 |

| 3010 | 700 | 870 | 1200 | 650 | 300 | 250 | 100 | 70 | 0.8 | 1.0 | 1.5 |

| 3012 | 700 | 890 | 1200 | 650 | 300 | 250 | 120 | 90 | 0.8 | 1.0 | 1.5 |

| 3015 | 700 | 920 | 1200 | 650 | 300 | 250 | 150 | 120 | 0.8 | 1.5 | 2.0 |

| 4510 | 700 | 900 | 1400 | 750 | 450 | 400 | 100 | 70 | 1.0 | 1.5 | 2.0 |

| 4512 | 700 | 920 | 1400 | 750 | 450 | 400 | 120 | 90 | 1.0 | 1.5 | 2.0 |

| 4515 | 700 | 950 | 1400 | 750 | 450 | 400 | 150 | 120 | 1.0 | 1.5 | 2.0 |

| 5010 | 700 | 900 | 1500 | 850 | 500 | 450 | 100 | 70 | 1.0 | 1.5 | 2.0 |

| 5012 | 700 | 920 | 1500 | 850 | 500 | 450 | 120 | 90 | 1.0 | 1.5 | 2.0 |

| 5015 | 700 | 950 | 1500 | 850 | 500 | 450 | 150 | 120 | 1.0 | 1.5 | 2.0 |

| 5020 | 700 | 1000 | 1600 | 850 | 500 | 450 | 200 | 170 | 1.5 | 2.0 | 2.5 |

| 5025 | 700 | 1050 | 1600 | 850 | 500 | 450 | 250 | 220 | 1.5 | 2.0 | 2.5 |

| 5030 | 700 | 1100 | 1600 | 850 | 500 | 450 | 300 | 270 | 2.0 | 2.5 | 3.0 |

| 6030 | 400 | 800 | 1800 | 950 | 600 | 550 | 300 | 270 | 2.5 | 3.0 | 3.5 |

| 6035 | 400 | 850 | 1800 | 950 | 600 | 550 | 350 | 320 | 3.0 | 3.5 | 4.0 |

| 6040 | 400 | 900 | 1800 | 950 | 600 | 550 | 400 | 370 | 3.5 | 4.0 | 4.5 |

| 6050 | 400 | 950 | 2000 | 950 | 600 | 50 | 500 | 470 | 4.0 | 5.0 | 5.5 |

| Speed:15-36 meter/min | |||||||||||

Notes:

All the sensitivity parameters above is on the basis of the test card detected on conveyor belt, the actual sensitivity will be affected by the product's features and working environment.

The above are commom models, the size can be customized according to your requirements.

LEARN MORE ABOUT OUR METAL EDTECTORS

Product Description

The COSO Metal Detector with Flap Rejection is designed for high-precision detection of metal contaminants in food, pharmaceutical, and packaging industries. Featuring a high-sensitivity detection system, this metal detector efficiently identifies and removes ferrous, non-ferrous, and stainless steel contaminants to ensure product quality. With its automatic flap rejection system, contaminants are immediately ejected from the production line, reducing the risk of contamination and ensuring smooth, uninterrupted operations. The detector is fully customizable with options for waterproof, dust-proof, and explosion-proof designs to meet the specific needs of your production environment.

Application

Product Details

Key Features

Flap Rejection System for automatic contaminant removal

High-Sensitivity Detection for accurate impurity identification

Customizable Design for specific industry needs

Ideal for food, pharma, and packaging industries

Produc Parameter

H1: Height from conveyor belt to the ground DB: Width of tunnel

H2: Height of whole machine TB: Passing width

L: Length of conveyor belt DH: Height of tunnel

W: Width of whole machine TH: Passing height

| Model | Size of whole machine(mm) | Size of detecting head(mm) | Best sensitivity(mm) | ||||||||

| H1 | H2 | L | W | DB | TB | DH | TH | Fe | Non-Fe | SUS | |

| 3008 | 700 | 850 | 1200 | 650 | 300 | 250 | 80 | 50 | 0.8 | 1.0 | 1.5 |

| 3010 | 700 | 870 | 1200 | 650 | 300 | 250 | 100 | 70 | 0.8 | 1.0 | 1.5 |

| 3012 | 700 | 890 | 1200 | 650 | 300 | 250 | 120 | 90 | 0.8 | 1.0 | 1.5 |

| 3015 | 700 | 920 | 1200 | 650 | 300 | 250 | 150 | 120 | 0.8 | 1.5 | 2.0 |

| 4510 | 700 | 900 | 1400 | 750 | 450 | 400 | 100 | 70 | 1.0 | 1.5 | 2.0 |

| 4512 | 700 | 920 | 1400 | 750 | 450 | 400 | 120 | 90 | 1.0 | 1.5 | 2.0 |

| 4515 | 700 | 950 | 1400 | 750 | 450 | 400 | 150 | 120 | 1.0 | 1.5 | 2.0 |

| 5010 | 700 | 900 | 1500 | 850 | 500 | 450 | 100 | 70 | 1.0 | 1.5 | 2.0 |

| 5012 | 700 | 920 | 1500 | 850 | 500 | 450 | 120 | 90 | 1.0 | 1.5 | 2.0 |

| 5015 | 700 | 950 | 1500 | 850 | 500 | 450 | 150 | 120 | 1.0 | 1.5 | 2.0 |

| 5020 | 700 | 1000 | 1600 | 850 | 500 | 450 | 200 | 170 | 1.5 | 2.0 | 2.5 |

| 5025 | 700 | 1050 | 1600 | 850 | 500 | 450 | 250 | 220 | 1.5 | 2.0 | 2.5 |

| 5030 | 700 | 1100 | 1600 | 850 | 500 | 450 | 300 | 270 | 2.0 | 2.5 | 3.0 |

| 6030 | 400 | 800 | 1800 | 950 | 600 | 550 | 300 | 270 | 2.5 | 3.0 | 3.5 |

| 6035 | 400 | 850 | 1800 | 950 | 600 | 550 | 350 | 320 | 3.0 | 3.5 | 4.0 |

| 6040 | 400 | 900 | 1800 | 950 | 600 | 550 | 400 | 370 | 3.5 | 4.0 | 4.5 |

| 6050 | 400 | 950 | 2000 | 950 | 600 | 50 | 500 | 470 | 4.0 | 5.0 | 5.5 |

| Speed:15-36 meter/min | |||||||||||

Notes:

All the sensitivity parameters above is on the basis of the test card detected on conveyor belt, the actual sensitivity will be affected by the product's features and working environment.

The above are commom models, the size can be customized according to your requirements.

LEARN MORE ABOUT OUR METAL EDTECTORS