close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

AEC500C

COSO

Product Description

The machine can be used in food, pharmaceutical, chemical, textile, garment, plastic, rubber industry etc, applying to detect metal pollution that was mixed with products or raw materials.Using this machine can help manufacturers achieve compliance,minimize risk of product recalls and reduce production downtime.

Application

Product Details

Key Features

Operating system has the funcction of one-button self-learning. Easy to operate and adjust for users.

It can store 100 kinds of product parameters for different products.

Adoptting modular design and installation that makes it easy to assemble and disassemeble.

Customization can be provided based on product's size,weight and other characteristics to achieve best detection results.

The rejection system type can be customized.

Product Parameter

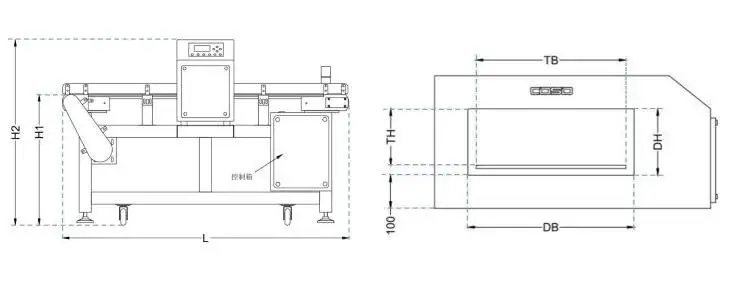

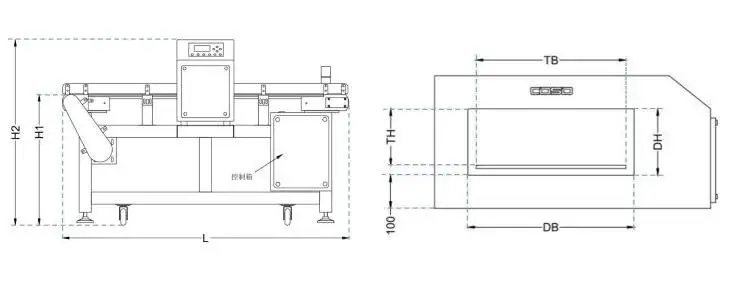

H1: Height from conveyor belt to the ground DB: Width of tunnel

H2: Height of whole machine TB: Passing width

L: Length of conveyor belt DH: Height of tunnel

W: Width of whole machine TH: Passing height

| Model | Size of whole machine(mm) | Size of detecting head(mm) | Best sensitivity(mm) | ||||||||

| H1 | H2 | L | W | DB | TB | DH | TH | Fe | Non-Fe | SUS | |

| 3008 | 700 | 850 | 1200 | 650 | 300 | 250 | 80 | 50 | 0.8 | 1.0 | 1.5 |

| 3010 | 700 | 870 | 1200 | 650 | 300 | 250 | 100 | 70 | 0.8 | 1.0 | 1.5 |

| 3012 | 700 | 890 | 1200 | 650 | 300 | 250 | 120 | 90 | 0.8 | 1.0 | 1.5 |

| 3015 | 700 | 920 | 1200 | 650 | 300 | 250 | 150 | 120 | 0.8 | 1.5 | 2.0 |

| 4510 | 700 | 900 | 1400 | 750 | 450 | 400 | 100 | 70 | 1.0 | 1.5 | 2.0 |

| 4512 | 700 | 920 | 1400 | 750 | 450 | 400 | 120 | 90 | 1.0 | 1.5 | 2.0 |

| 4515 | 700 | 950 | 1400 | 750 | 450 | 400 | 150 | 120 | 1.0 | 1.5 | 2.0 |

| 5010 | 700 | 900 | 1500 | 850 | 500 | 450 | 100 | 70 | 1.0 | 1.5 | 2.0 |

| 5012 | 700 | 920 | 1500 | 850 | 500 | 450 | 120 | 90 | 1.0 | 1.5 | 2.0 |

| 5015 | 700 | 950 | 1500 | 850 | 500 | 450 | 150 | 120 | 1.0 | 1.5 | 2.0 |

| 5020 | 700 | 1000 | 1600 | 850 | 500 | 450 | 200 | 170 | 1.5 | 2.0 | 2.5 |

| 5025 | 700 | 1050 | 1600 | 850 | 500 | 450 | 250 | 220 | 1.5 | 2.0 | 2.5 |

| 5030 | 700 | 1100 | 1600 | 850 | 500 | 450 | 300 | 270 | 2.0 | 2.5 | 3.0 |

| 6030 | 400 | 800 | 1800 | 950 | 600 | 550 | 300 | 270 | 2.5 | 3.0 | 3.5 |

| 6035 | 400 | 850 | 1800 | 950 | 600 | 550 | 350 | 320 | 3.0 | 3.5 | 4.0 |

| 6040 | 400 | 900 | 1800 | 950 | 600 | 550 | 400 | 370 | 3.5 | 4.0 | 4.5 |

| 6050 | 400 | 950 | 2000 | 950 | 600 | 50 | 500 | 470 | 4.0 | 5.0 | 5.5 |

| Speed:15-36 meter/min | |||||||||||

Notes:

All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; the actual sensitivity may be different accordingly to the characteristics of the tested products or the working environment, it should be based on the actual detection sensitivity.

Models listed in the table are just standard configurations. Our actual production includes numerous variants not exhaustively listed here. For other requirements, please contact customer service for details.

LEARN MOER ABOUT OUR METAL DETECTORS

Product Description

The machine can be used in food, pharmaceutical, chemical, textile, garment, plastic, rubber industry etc, applying to detect metal pollution that was mixed with products or raw materials.Using this machine can help manufacturers achieve compliance,minimize risk of product recalls and reduce production downtime.

Application

Product Details

Key Features

Operating system has the funcction of one-button self-learning. Easy to operate and adjust for users.

It can store 100 kinds of product parameters for different products.

Adoptting modular design and installation that makes it easy to assemble and disassemeble.

Customization can be provided based on product's size,weight and other characteristics to achieve best detection results.

The rejection system type can be customized.

Product Parameter

H1: Height from conveyor belt to the ground DB: Width of tunnel

H2: Height of whole machine TB: Passing width

L: Length of conveyor belt DH: Height of tunnel

W: Width of whole machine TH: Passing height

| Model | Size of whole machine(mm) | Size of detecting head(mm) | Best sensitivity(mm) | ||||||||

| H1 | H2 | L | W | DB | TB | DH | TH | Fe | Non-Fe | SUS | |

| 3008 | 700 | 850 | 1200 | 650 | 300 | 250 | 80 | 50 | 0.8 | 1.0 | 1.5 |

| 3010 | 700 | 870 | 1200 | 650 | 300 | 250 | 100 | 70 | 0.8 | 1.0 | 1.5 |

| 3012 | 700 | 890 | 1200 | 650 | 300 | 250 | 120 | 90 | 0.8 | 1.0 | 1.5 |

| 3015 | 700 | 920 | 1200 | 650 | 300 | 250 | 150 | 120 | 0.8 | 1.5 | 2.0 |

| 4510 | 700 | 900 | 1400 | 750 | 450 | 400 | 100 | 70 | 1.0 | 1.5 | 2.0 |

| 4512 | 700 | 920 | 1400 | 750 | 450 | 400 | 120 | 90 | 1.0 | 1.5 | 2.0 |

| 4515 | 700 | 950 | 1400 | 750 | 450 | 400 | 150 | 120 | 1.0 | 1.5 | 2.0 |

| 5010 | 700 | 900 | 1500 | 850 | 500 | 450 | 100 | 70 | 1.0 | 1.5 | 2.0 |

| 5012 | 700 | 920 | 1500 | 850 | 500 | 450 | 120 | 90 | 1.0 | 1.5 | 2.0 |

| 5015 | 700 | 950 | 1500 | 850 | 500 | 450 | 150 | 120 | 1.0 | 1.5 | 2.0 |

| 5020 | 700 | 1000 | 1600 | 850 | 500 | 450 | 200 | 170 | 1.5 | 2.0 | 2.5 |

| 5025 | 700 | 1050 | 1600 | 850 | 500 | 450 | 250 | 220 | 1.5 | 2.0 | 2.5 |

| 5030 | 700 | 1100 | 1600 | 850 | 500 | 450 | 300 | 270 | 2.0 | 2.5 | 3.0 |

| 6030 | 400 | 800 | 1800 | 950 | 600 | 550 | 300 | 270 | 2.5 | 3.0 | 3.5 |

| 6035 | 400 | 850 | 1800 | 950 | 600 | 550 | 350 | 320 | 3.0 | 3.5 | 4.0 |

| 6040 | 400 | 900 | 1800 | 950 | 600 | 550 | 400 | 370 | 3.5 | 4.0 | 4.5 |

| 6050 | 400 | 950 | 2000 | 950 | 600 | 50 | 500 | 470 | 4.0 | 5.0 | 5.5 |

| Speed:15-36 meter/min | |||||||||||

Notes:

All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; the actual sensitivity may be different accordingly to the characteristics of the tested products or the working environment, it should be based on the actual detection sensitivity.

Models listed in the table are just standard configurations. Our actual production includes numerous variants not exhaustively listed here. For other requirements, please contact customer service for details.

LEARN MOER ABOUT OUR METAL DETECTORS