close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

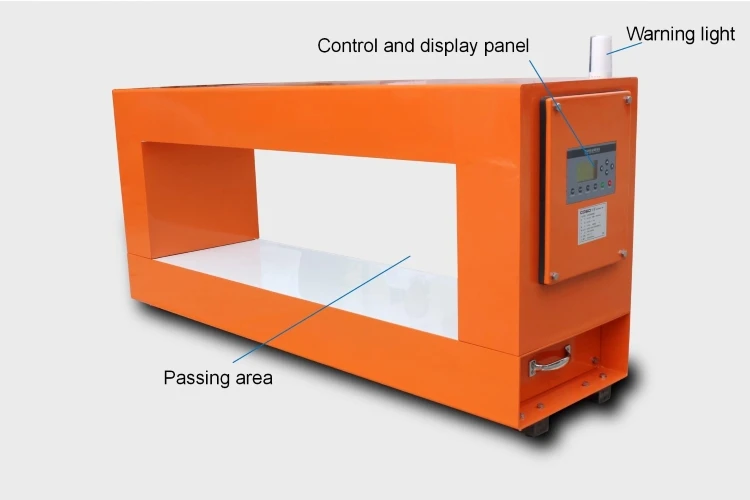

SEC1000

COSO

Product Description

This machine is used for detecting metallic impurities left or mixed with products.It can be applied in plastic, building material, wood, paper making, coal, mining, cement, waste process and renewable resource industry etc. It can be divided into two parts and installed to your productin line without cutting the belt.

SEC series online metal detector can eliminate signal interference that is caused by products themselves or conveyor belt by using DSP intelligent technology.

Application

Product Details

Key Features

The machine has function of one-button seif-learning process which can automatically set parameters precisely, no need for human to adjust and avoid complex debugging.

It can store 100 kinds of product parameters for different products.

The LCD screen is convenient to operate.

The conveyor belt is generally installed horizontally, but it can be applied to different angle according to your request.

When the impurity is detected, the machine will send signal to your control system.

Product Parameter

| Tunnel width(mm) | Tunnel height(mm) | Passing width(mm) | Passing height(mm) | Best sensitivity(mm) | |

| Fe Φ | SUS Φ | ||||

| 1000 | 200 | 800 | 150 | 2.6 | 4.0 |

| 1000 | 250 | 800 | 200 | 3.5 | 5.3 |

| 1000 | 300 | 600 | 250 | 4.2 | 6.3 |

| 1000 | 350 | 600 | 300 | 4.5 | 6.5 |

| 1000 | 400 | 600 | 350 | 5.2 | 7.8 |

| 1000 | 450 | 600 | 400 | 6.1 | 9.2 |

| 1000 | 500 | 600 | 450 | 6.8 | 10.3 |

| 1200 | 200 | 1000 | 150 | 2.9 | 4.4 |

| 1200 | 300 | 1000 | 250 | 4.5 | 6.8 |

| 1200 | 400 | 800 | 350 | 5.6 | 8.4 |

| 1200 | 500 | 800 | 450 | 7.5 | 12.0 |

| 1400 | 300 | 1200 | 250 | 5.0 | 7.5 |

| 1400 | 500 | 1000 | 450 | 8.6 | 13.0 |

| 1600 | 600 | 1200 | 500 | 9.0 | 15.5 |

| 1600 | 900 | 1200 | 800 | 12.0 | 21.0 |

Notes:

All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; the actual sensitivity may be different accordingly to the characteristics of the tested products or the working environment, it should be based on the actual detection sensitivity.

Models listed in the table are just standard configurations. Our actual production includes numerous variants not exhaustively listed here. For other requirements, please contact customer service for details.

LEARN MORE ABOUT OUR METAL DETECTORS

Product Description

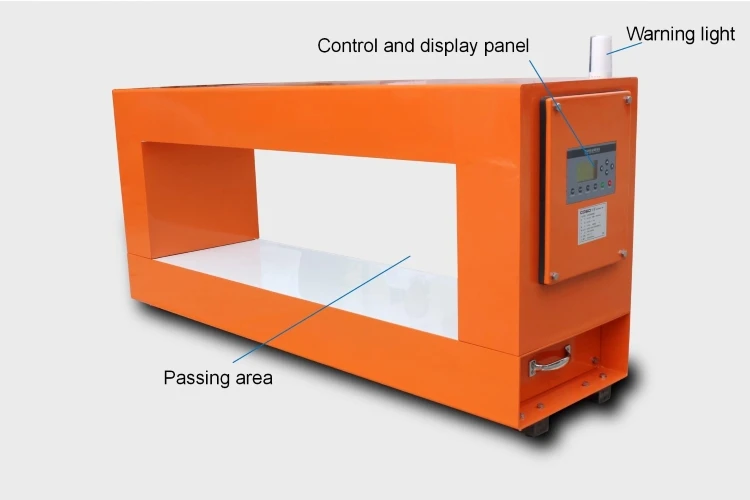

This machine is used for detecting metallic impurities left or mixed with products.It can be applied in plastic, building material, wood, paper making, coal, mining, cement, waste process and renewable resource industry etc. It can be divided into two parts and installed to your productin line without cutting the belt.

SEC series online metal detector can eliminate signal interference that is caused by products themselves or conveyor belt by using DSP intelligent technology.

Application

Product Details

Key Features

The machine has function of one-button seif-learning process which can automatically set parameters precisely, no need for human to adjust and avoid complex debugging.

It can store 100 kinds of product parameters for different products.

The LCD screen is convenient to operate.

The conveyor belt is generally installed horizontally, but it can be applied to different angle according to your request.

When the impurity is detected, the machine will send signal to your control system.

Product Parameter

| Tunnel width(mm) | Tunnel height(mm) | Passing width(mm) | Passing height(mm) | Best sensitivity(mm) | |

| Fe Φ | SUS Φ | ||||

| 1000 | 200 | 800 | 150 | 2.6 | 4.0 |

| 1000 | 250 | 800 | 200 | 3.5 | 5.3 |

| 1000 | 300 | 600 | 250 | 4.2 | 6.3 |

| 1000 | 350 | 600 | 300 | 4.5 | 6.5 |

| 1000 | 400 | 600 | 350 | 5.2 | 7.8 |

| 1000 | 450 | 600 | 400 | 6.1 | 9.2 |

| 1000 | 500 | 600 | 450 | 6.8 | 10.3 |

| 1200 | 200 | 1000 | 150 | 2.9 | 4.4 |

| 1200 | 300 | 1000 | 250 | 4.5 | 6.8 |

| 1200 | 400 | 800 | 350 | 5.6 | 8.4 |

| 1200 | 500 | 800 | 450 | 7.5 | 12.0 |

| 1400 | 300 | 1200 | 250 | 5.0 | 7.5 |

| 1400 | 500 | 1000 | 450 | 8.6 | 13.0 |

| 1600 | 600 | 1200 | 500 | 9.0 | 15.5 |

| 1600 | 900 | 1200 | 800 | 12.0 | 21.0 |

Notes:

All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; the actual sensitivity may be different accordingly to the characteristics of the tested products or the working environment, it should be based on the actual detection sensitivity.

Models listed in the table are just standard configurations. Our actual production includes numerous variants not exhaustively listed here. For other requirements, please contact customer service for details.

LEARN MORE ABOUT OUR METAL DETECTORS