close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-27 Origin: Site

Are you tired of worrying about metal contaminants in your food products, leading to costly recalls and brand damage? Are you tired of receiving low prices for your recycled plastics due to excessive impurities? Are you tired of feeling overwhelmed by the vast array of separators on the market, unsure which one to choose? A high-quality separator is the key to solving these problems. This comprehensive guide will take you through everything you need to know to make an informed and confident decision.

What is Metal Separator?

A separator is a piece of equipment designed to separate and remove metallic materials from a mixed materials, playing a important role in ensuring product safety, enhancing raw material purity, recovering valuable materials, and protecting downstream machinery.

How Does a Separator Work?

Separators operate on different physical principles to target specific metals.

The two most common are:

Magnetic Separation: A strong magnetic field attracts ferrous metals in the material flow. Ferrous materials (such as iron and steel) are pulled out of the waste stream, while non-ferrous materials continue onward.

Eddy Current Separation: This technique employs a rapidly alternating magnetic field to induce electrical "eddy currents" in non-ferrous metals (like aluminum and copper). These currents create their own opposing magnetic field, which repels the metal, ejecting it from the material stream.

Types of Working Principles and Their Applications

Type | Working Principle | Ideal Applications | Target Materials |

Magnetic Separator | Magnetic Attraction | Recycling, Mining, Plastics, Food | Ferrous Metals |

Eddy Current Separator | Eddy Current Effect | Solid Waste Recycling | Non-Ferrous Metals |

Different Types of Metal Separators

It is ideally suited for granules, flakes, powder, and slices, available in both bulk and packaged forms.

Key Advantage: It eliminates quickly, and reduces the loss of materials and does not interfere with the normal production process. Different apertures can be chosen. It's compact and easy to install and integrate into existing pipelines conveniently.

Metal Separator Specific for Powder (Y-Type)

It is ideally suited for various powders, and mixtures of granules and powders.

Key Advantage: The unique Y-type design effectively prevents material leakage, ensuring a stable detection environment and minimizing the loss of valuable raw materials.

Metal Separator (Open-Type)

It is ideally suited for block, sheet, and other irregularly-shaped materials.

Key Advantage: The open-rejection mechanism prevents blockages and significantly reduces product carry-over loss, maximizing recovery value.

It is ideally suited for chili paste, jam, peanut butter, salad dressing, chocolate sauce, yogurt, juice and other liquid substances.

Key Advantage: Provides online, continuous metal purification for pipeline conveying systems.

Pharmaceutical Metal Separator

It is ideally suited for plain tablet, coated tablet, bilayered tablet, hard gelatin capsules, tab in tab and pill etc.

Key Advantage: Strictly adheres to pharmaceutical standards (e.g., GMP), ensuring drug safety and regulatory compliance.

It is ideally suited for recycled materials, including iron and non-ferrous metals such as copper, aluminum, stainless steel and so on.

Key Advantage: Enables unmanned operation, directly saving labor costs and reducing contamination risks.

Vibratory-Feeding Metal Separator

It is ideally suited for recycled materials, including iron and non-ferrous metals such as copper, aluminum, stainless steel and so on.

Key Advantage: Ensures even material feeding via vibration, effectively solving inlet clogging issues and guaranteeing continuous production.

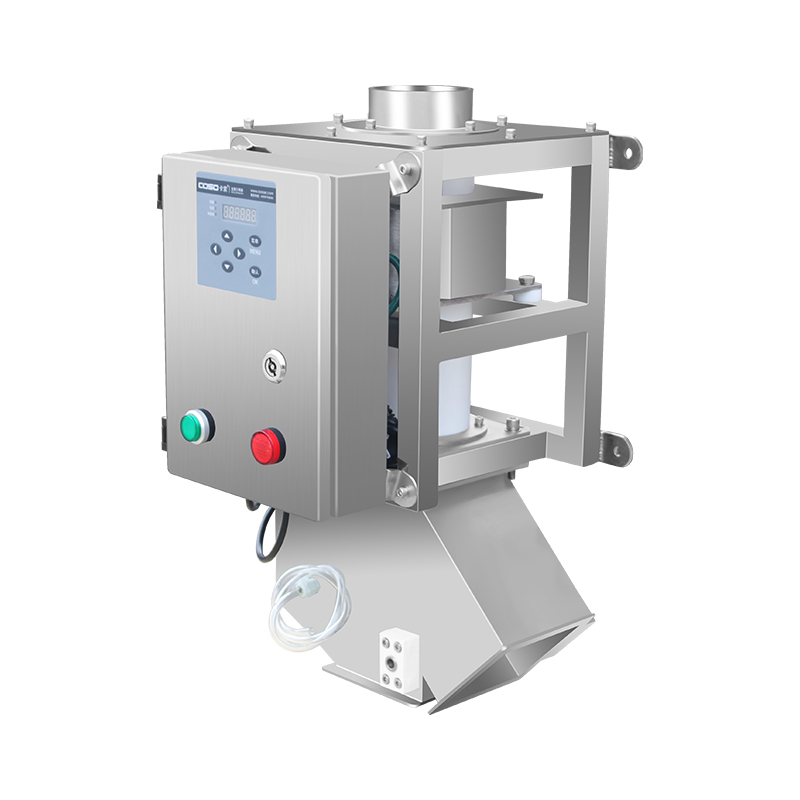

Pneumatic Conveying Pipes Metal Separator

It is ideally suited for integration into positive or negative pressure conveying pipelines.

Key Advantage: Features rapid rejection and minimal product loss, perfectly suited for the high-efficiency nature of pneumatic systems.

How to Choose the Right Separator for Your Business?

Step 1: Define Your Objective

Clarify your primary goal. Are you aiming for safety inspection (e.g., detecting contaminants) or resource recovery (e.g., separating valuable materials)? This fundamental choice dictates the technology path.

Step 2: Analyze Your Material

Understand the features of the material stream. Key factors include its composition (what materials are present, granule, powder, paste,liquid or others), moisture content, and particle size distribution or others.

Step 3: Determine Operational Requirements

Specify your production needs. This includes the required throughput (e.g., L/h), the desired level of automation, and the overall budget.

Step 4: Consider the Operating Environment

Account for any special conditions where the equipment will be used. Common requirements include food-grade (sanitary) standards, explosion-proof certifications for hazardous areas, or waterproof ratings.

Tailored Solutions for Your Industry Success

Discover how our separators deliver targeted value and a compelling return on investment across key sectors.

Food Industry: Ensuring Safety and Compliance

Safeguard your brand and consumers with our precision detection solutions. Metal separators are engineered to exceed rigorous food safety regulations, offering unparalleled detection sensitivity to identify the smallest contaminants. They are an integral part of your HACCP plan, providing documented proof of due diligence and preventing catastrophic recalls. Thus,your products won't be recalled.

Pharmaceutical Industry: Ensuring Product Purity & Regulatory Compliance

Advanced metal separation solutions safeguard pharmaceutical production by detecting and removing ferrous, non-ferrous, and stainless steel contaminants from raw materials to finished products. Designed to meet cGMP and FDA standards with full validation support (Installation Qualification/Operational Qualification/Performance Qualification), they ensure patient safety, minimize operational risks, and protect your brand reputation.

Scrap & Recycling: Maximizing Material Value

Transform your operation from cost center to profit center. Separators dramatically improve sorting purity, enabling you to produce high-value, clean material bales. This directly increases your recycling revenue by meeting stricter specifications and capturing more valuable non-ferrous metals like aluminum and copper from waste streams.

Plastics Recycling: Protecting Assets and Enhancing Output

Secure your production line and product quality. By separating metal contaminants, the separation systems protect expensive injection molding machines and extruders from catastrophic damage to screws and barrels. Simultaneously, they enhance the quality of your recycled plastic flakes, allowing you to command higher prices and access more demanding markets.

Why Choose Us? Your Partner in Detection Excellence

Founded in 2005, Dongguan Coso Electronic Tech Co., Ltd is headquartered in Dongguan, Guangdong, China, a globally renowned manufacturing center. We are a technology-driven enterprise specializing in the R&D and production of foreign object and weight detection equipment. Adopting a modular design principle, we integrate intelligent detection algorithms and precision manufacturing processes to provide customized solutions, including metal detection & separation, automatic weighing & sorting, and foreign object & defect detection for global manufacturing industries such as food, pharmaceuticals, plastics & rubber, packaging, mining, personal care, textiles, apparel, toys and chemical manufacturing. Our products include industrial metal detectors, metal separators, checkweighers, weight sorting machines, and X-ray inspection systems. With over 20 years of technological expertise, we have built a fully integrated industrial ecosystem covering R&D, production, sales, and service. We hold ISO9001 certification and possess more than 20 national patents. Our products comply with globally recognized standards (CE, FDA, RoHS) and have been exported to over 90 countries and regions. We have established cooperative relationships with numerous Fortune Global 500 enterprises. With sales and service centers in both the Pearl River Delta and Yangtze River Delta regions, our distribution network covers the entire country. The company is accelerating its global market expansion by establishing overseas service hubs and localized teams, striving to deliver high-quality products and services to customers worldwide. We continuously advance detection technology to support the evolution of global intelligent manufacturing through innovation and product development. We are committed to ensuring every product stands the test of the market, aiming to be a worldwide reliable detection equipment manufacturer.

Positioning Professional Manufacturer of Foreign Object & Weight Detection Equipment

Mission Make Production More Efficient Make Products More Reliable

Vision Being a Worldwide Reliable Detection Equipment Manufacturer

Values Intergrity Responsibility Excellence Innovation Gratitude Mutual Success

Brand Advantages

One-stop Customized Solutions

With strong R&D capabilities, customization expertise, a diverse product range, and professional service experience, COSO provides one-stop detection and sorting solutions for clients across industries, ensuring efficiency, cost-effectiveness, and peace of mind.

Reliable Quality with Low Maintenance Costs

COSO adopts user-friendly, intelligent and modular design principle with professional manufacturing capabilities to build a reliable product system that is easy to install, operate,and maintain. Backed by a mature supply chain network and economies of scale, we reduce spare parts and maintenance costs, ensruing customers’ zero post-purchase concerns.

Trusted by Leading Enterprises

For over 20 years, COSO’s products have been exported to over 90 countries and regions, serving more than 12,000 quality clients across 200+ industries. We have established cooperative relationships with numerous Fortune Global 500 enterprises.

COOPERATIVE PARTNER

Our growth has been paved with the trust of numerous outstanding partners. We deeply understand that every collaboration is more than just business dealings; it's about shared values and co-creating value. We are honored to have provided reliable solutions to many leading companies, including Danone, Ferrero, Nestlé, Toyota, Huawei, Foxconn, Mattel, Taiwan Cement and Bridgestone etc., deepening our understanding of the needs of different industries in the process. This valuable experience gives us even more confidence and capability to become your most trusted partner.

Conclusion

Selecting the right metal separator hinges on a accurate understanding of technological principles, operational demands, and industry-specific problems. By aligning your needs with the solutions outlined in this guide, from magnetic and eddy current systems to advanced metal detectors, you can enhance product integrity, boost profitability, and future-proof your operations. Partner with experts to implement tailored separation strategies that deliver measurable Return on Investment.